316L STAINLESS STEEL H BEAM

Classification :

Application: Building /Construction/Steel Frame

Material: 201,202,301,304,321,316,316L,etc

Keywords:

H Beam

Product Description

|

Product Name |

316L stainless steel H beam |

|

Thickness |

3mm-12mm |

|

Size |

40*20/50*25/60*30/70*35/80*40/90*45/100*50/120*60/130*65/ |

|

Technique |

Hot Rolled |

|

Application |

Building /Construction/Steel Frame |

|

Material |

201,202,301,304,321,316,316L,etc |

Stainless steel H beam size

| Size | Depth flange | Web | Flange thickness | Weight |

| width(mm) | thickness(mm) | (mm) | (kg/m) | |

| IPE100 | 100×55 | 4.1 | 5.7 | 8.1 |

| IPE120 | 120×64 | 4.4 | 6.3 | 10.4 |

| IPE140 | 140×73 | 4.7 | 6.9 | 12.9 |

| IPE160 | 160×82 | 5 | 7.4 | 15.8 |

| IPE180 | 180×91 | 5.3 | 8 | 18.8 |

| IPE200 | 200×100 | 5.6 | 8.5 | 22.4 |

| IPE220 | 220×110 | 5.9 | 9.2 | 26.2 |

| IPE240 | 240×120 | 6.2 | 9.8 | 30.7 |

| IPE270 | 270×135 | 6.6 | 10.2 | 36.1 |

Chemical Composition

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0- |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 - |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13 .0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2 .0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 . 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | - |

Surface Description

| Surface | Definition | Application |

| No.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe etc. |

| No.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction etc. |

| No.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment etc. |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. |

Medical equipment, Food industry, Construction material, Kitchen utensils etc. |

| BA (No.6) | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction etc. |

| Mirror (No.8) | Shinning like a mirror | Building construction, decoration etc. |

| Hairline | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction etc. |

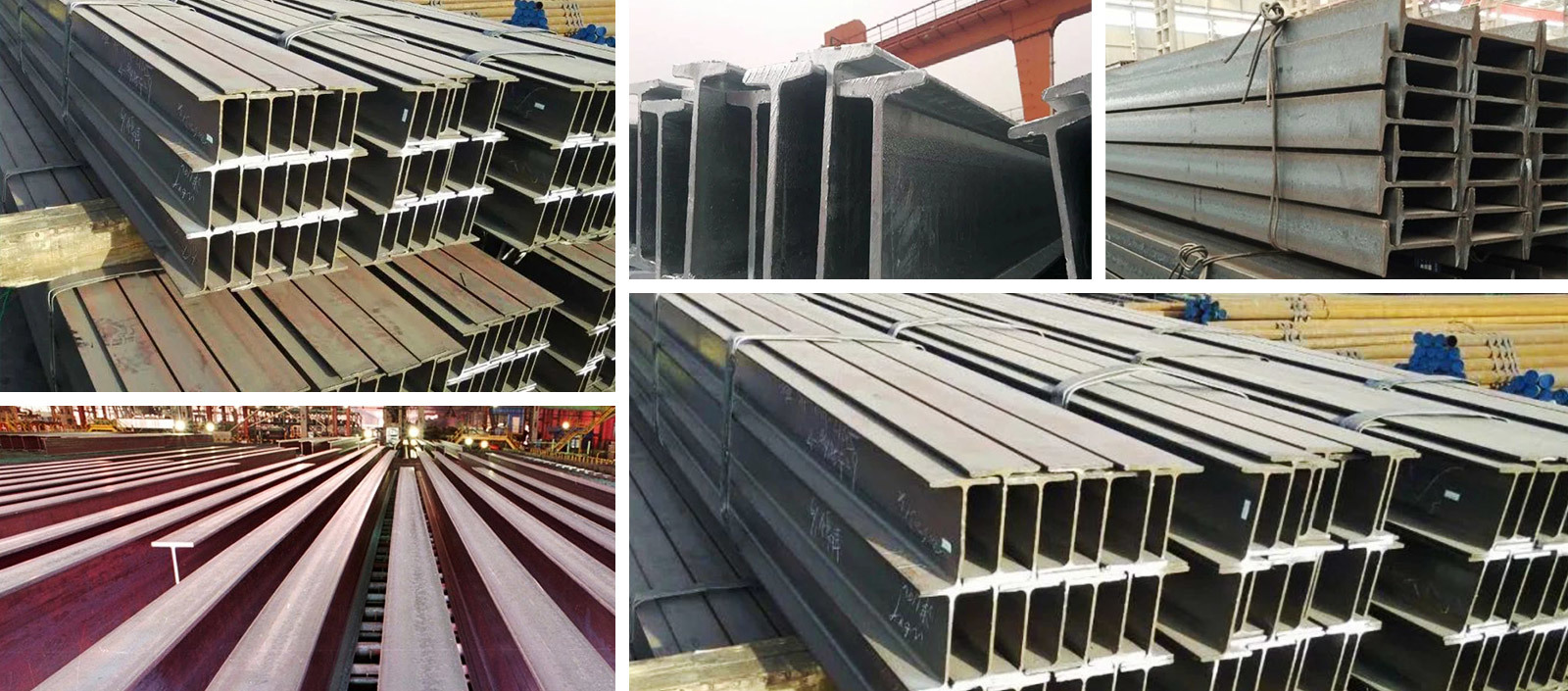

warehouse storage

The annual output of the factory is 400,000 tons, and the current inventory is more than 100,000 tons, which can greatly save the purchasing time of customers and ensure the production cycle and product quality of customers. We are a quality partner for domestic and foreign customers. At present, there are 14 steel production lines for processing, bending, coating, heat treatment, cutting, drilling, chamfering, conditioning, surface treatment and 13 sets of processing equipment.

Packing and shipping

Our main products are: carbon steel plate, carbon steel pipe, carbon steel coil, stainless steel plate, stainless steel coil, stainless steel profile, galvanized plate, galvanized coil, color coated steel coil, ppgi/ppgl and a wide range of high quality steel products.

Customer visit

Li Cheng (Shandong) Metal Materials Co., LTD. has the right to import and export, and its products are exported to more than 20 countries in Asia, Africa, Europe, North America and other regions. Complete processing equipment, perfect quality assurance system, well received by customers.We are willing to first-class technology, first-class equipment, first-class service wholeheartedly and friends from all walks of life sincere cooperation!

Cooperation Case

Applicable to construction, petroleum, chemical, electric power, metallurgy, urban gas, heat pipe network, Bridges, railways, vehicles, ships and other industrial fields and construction, infrastructure and other engineering fields. Complete testing equipment, strong technical force, can implement GB, ASTM, JIS, DIN and other standards.

HONOR

Factory

FACTORY

FACTORY

FACTORY

FACTORY

FACTORY

FACTORY

RELATED PRODUCTS

GET A FREE QUOTE