WearTuf 400 Abrasion Resistant Steel Plates

Classification :

resistance with outstanding weldability and cold forming capabilities.

Keywords:

Wear Resistant Steel Plate

Product Introduction

Characteristics

WearTuf 400 is a fully martensitic Q&T abrasion resistant steel plate, having a hardness of average 400 Brinell. WearTuf 400 is a versatile wear plate that combines abrasion resistance with outstanding weldability and cold forming capabilities. The high impact toughness grants a very good crack resistance of the steel during fabrication and in service.

Dimensions

WearTuf 400 is supplied in the thickness rage of 4.0 - 50.0 mm and in the plate width of 900 – 3 100 mm. Supplied plate length from 4 000 to 18 000 mm.

Impact toughness

Typical 45J/-40°C (-40°F)

The impact toughness is given as absorbed energy at temperature, being the average of three full size Charpy-V test samples in longitudinal direction to rolling, according to EN ISO 148-1.

Hardness guarantee

Surface hardness:370-430 Brinell

Guaranteed hardness range, measured on a milled surface at a depth of 0.5 – 2.0 mm below the plate surface, according to ISO EN 6506-1.

Min center hardness:

Plate thickness ≤ 20mm: min 370 Brinell

Plate thickness > 20mm: 95% of min guaranteed surface hardness.

Applications

WearTuf 400 has found its application base among the traditional earth moving, mining and transport equipment, such as buckets, dumpers, tippers, crushers, hammers, conveyors and other mineral feeding systems. Being supplied in the thin and wide dimension range, WearTuf 400 also focuses on light weight wear design concepts and applications.

Ultrasonic testing

All plates delivered meets the Class E1, S1 requirement, according to EN 10 160.

Delivery condition

WearTuf 400 is delivered in the as quenched (Q) condition, and when found necessary in the condition of quenched and tempered (QT).

The plates are delivered with sheared or thermally cut edges.

Tolerances

The thickness tolerances of WearTuf 400 meets and exceeds the thickness tolerance of EN 10 029

Class A . Tolerances on shape, length, and width meets the requirements of EN 10029. Flatness tolerances conforms to EN 10 029 Class S or closer.

Surface condition and properties

The delivered surface finish meets and exceeds that of EN 10163-2 Class A, Subclass 3.

The plates will be delivered as shot painted, using a low zinc silicate corrosion protective shop primer. Plates can also be delivered as unpainted.

Heat Treatment

Since the properties in the as delivery condition cannot be retained after exposure at service temperatures above 250°C, WearTuf 400 is not intended for any further heat treatment.

Processing performance

1) Bending,

2) Welding,

3) Cutting

4) Machining

Technical Data

Chemical Composition

Ladle analysis: The steel is grain refined and fully killed, wt%

| Thickness (mm) |

C max |

Si max |

Mn max |

P max |

S max |

Cr max |

Ni max |

Mo max |

B max |

CEV Typical |

CET Typical |

| 4.0 – 12.0 | 0.18 | 0.50 | 1.50 | 0.025 | 0.010 | 0.40 | 0.10 | 0.20 | 0.004 | 0.36 | 0.25 |

| 12.1 – 25.0 | 0.20 | 0.50 | 1.50 | 0.025 | 0.010 | 0.60 | 0.15 | 0.25 | 0.004 | 0.45 | 0.29 |

| 25.1 – 40.0 | 0.20 | 0.50 | 1.50 | 0.025 | 0.010 | 1.00 | 0.20 | 0.35 | 0.004 | 0.56 | 0.33 |

| 40.1 – 50.0 | 0.21 | 0.7 | 1.50 | 0.025 | 0.010 | 1.20 | 0.25 | 0.50 | 0.004 | 0.62 | 0.35 |

CEV = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15

CET = C + (Mn + Mo)/10 + (Cr + Cu)/20 + Ni/40

Mechanical Properties

| Yield strength Rp0.2 |

Tensile strength Rm |

Elongation A5 |

| 1000 MPa | 1250 MPa | 10% |

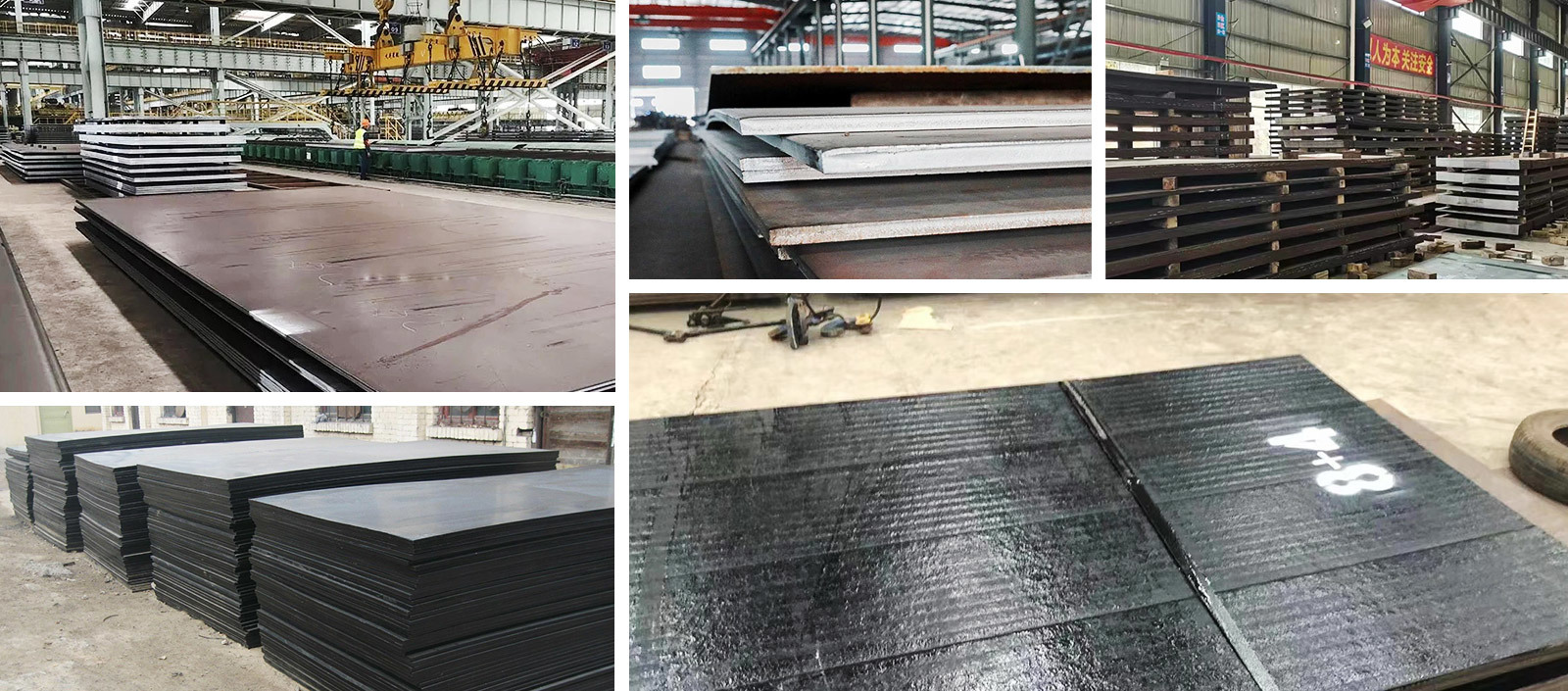

warehouse storage

The annual output of the factory is 400,000 tons, and the current inventory is more than 100,000 tons, which can greatly save the purchasing time of customers and ensure the production cycle and product quality of customers. We are a quality partner for domestic and foreign customers. At present, there are 14 steel production lines for processing, bending, coating, heat treatment, cutting, drilling, chamfering, conditioning, surface treatment and 13 sets of processing equipment.

Packing and shipping

Our main products are: carbon steel plate, carbon steel pipe, carbon steel coil, stainless steel plate, stainless steel coil, stainless steel profile, galvanized plate, galvanized coil, color coated steel coil, ppgi/ppgl and a wide range of high quality steel products.

Customer visit

Li Cheng (Shandong) Metal Materials Co., LTD. has the right to import and export, and its products are exported to more than 20 countries in Asia, Africa, Europe, North America and other regions. Complete processing equipment, perfect quality assurance system, well received by customers.We are willing to first-class technology, first-class equipment, first-class service wholeheartedly and friends from all walks of life sincere cooperation!

Cooperation Case

Applicable to construction, petroleum, chemical, electric power, metallurgy, urban gas, heat pipe network, Bridges, railways, vehicles, ships and other industrial fields and construction, infrastructure and other engineering fields. Complete testing equipment, strong technical force, can implement GB, ASTM, JIS, DIN and other standards.

HONOR

Factory

FACTORY

FACTORY

FACTORY

FACTORY

FACTORY

FACTORY

RELATED PRODUCTS

GET A FREE QUOTE