SA387 GR.11 CL 1 Cr-Mo Alloy Pressure Vessel Steel Plate

Classification :

Keywords:

Boiler Pressure Vessel Steel

SA387 GR.11 CL 1 Alloy Pressure Vessel Steel Plate Descriptions:

ASME SA387 Gr 11 CL 1 is a chromium molybdenum alloy steel plate intended primarily for welded boiler and pressure vessels designed of elevated temperature service.

The Cr content 1.25% and the Mo content 0.5%.

Chrome moly plate under ASME SA387 in serveral grades that has different alloy contents as below, common use grades are Gr 11, 12,22, 5, 9 and 91.

Chemical Composition and Mechanical Properties:

| SA387 Gr.11 CL.1Chemical Composition | |||||||

| Grade | The Element Max (%) | ||||||

| C | Si | Mn | P | S | Cr | Mo | |

| SA387 Gr.11 Cl.1 | 0.04-0.17 | 0.44-0.86 | 0.35-0.73 | 0.035 | 0.035 | 0.94-1.56 | 0.40-0.70 |

| Grade | SA387 Gr.11 CL.1Mechanical Property | |||

| Thickness | Yield | Tensile | Elongation | |

| SA387 Gr.11 Cl.1 | mm | Min Mpa | Mpa | Min % |

| t≦50 | 240 | 415-585 | 22 | |

| 50<t≦200 | 240 | 415-585 | 19 | |

Refered Standards for ASTM A387 Alloy Steel Plate

ASTM

- A20/A20M: General requirements for pressure vessel plates.

- A370: Test specification for mechanical properties of steel

- A435/A435M: For straight-beam ultrasonic examination of steel plates

- A577/A577M: For ultrasonic angle beam examination of steel plates

- A578/A578M: For straight beam UT examination of rolled steel plates in special applications

- A1017/A1017M: Specification for pressure vessle plates of alloy steel, chromium-molybdenum-tungsten

AWS Specification

- A5.5/A5.5M: Low alloy steel electrodes for shield metal arc welding.

- A5.23/A5.23M: Low alloy steel electrodes for fulxes for submerged arc welding.

- A5.28/A5.28M: For gas shielded arc welding

- A5.29/A5.29M: For flux cored arc welding.

Heat Treatment for A387 Chrom Moly Alloy Steel Plate

Chrome moly alloy steel plate under ASTM A387 shall be killed steel, with thermally treated either by annealing, normarlizing and tempering. Or in case agreed by buyer, accelerated cooling from the austenitizing temperature by air blasting or liquid quenching, followed by tempering, minimum tempering temperatures shall be as below table:

| Grade | Temperature, °F [°C] |

| 2, 12 and 11 | 1150 [620] |

| 22, 22L, 21, 21L and 9 | 1250 [675] |

| 5 | 1300 [705] |

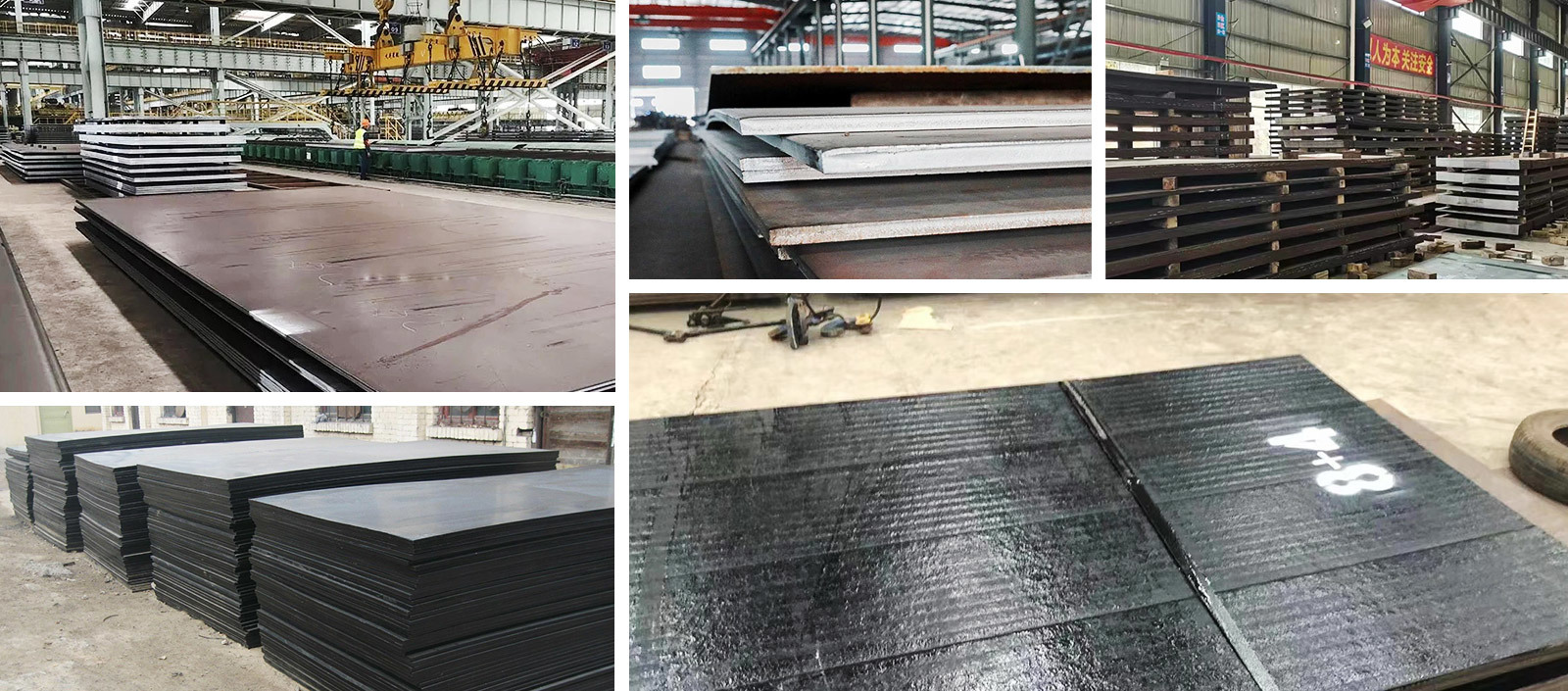

warehouse storage

The annual output of the factory is 400,000 tons, and the current inventory is more than 100,000 tons, which can greatly save the purchasing time of customers and ensure the production cycle and product quality of customers. We are a quality partner for domestic and foreign customers. At present, there are 14 steel production lines for processing, bending, coating, heat treatment, cutting, drilling, chamfering, conditioning, surface treatment and 13 sets of processing equipment.

Packing and shipping

Our main products are: carbon steel plate, carbon steel pipe, carbon steel coil, stainless steel plate, stainless steel coil, stainless steel profile, galvanized plate, galvanized coil, color coated steel coil, ppgi/ppgl and a wide range of high quality steel products.

Customer visit

Li Cheng (Shandong) Metal Materials Co., LTD. has the right to import and export, and its products are exported to more than 20 countries in Asia, Africa, Europe, North America and other regions. Complete processing equipment, perfect quality assurance system, well received by customers.We are willing to first-class technology, first-class equipment, first-class service wholeheartedly and friends from all walks of life sincere cooperation!

Cooperation Case

Applicable to construction, petroleum, chemical, electric power, metallurgy, urban gas, heat pipe network, Bridges, railways, vehicles, ships and other industrial fields and construction, infrastructure and other engineering fields. Complete testing equipment, strong technical force, can implement GB, ASTM, JIS, DIN and other standards.

HONOR

Factory

FACTORY

FACTORY

FACTORY

FACTORY

FACTORY

FACTORY

RELATED PRODUCTS

GET A FREE QUOTE