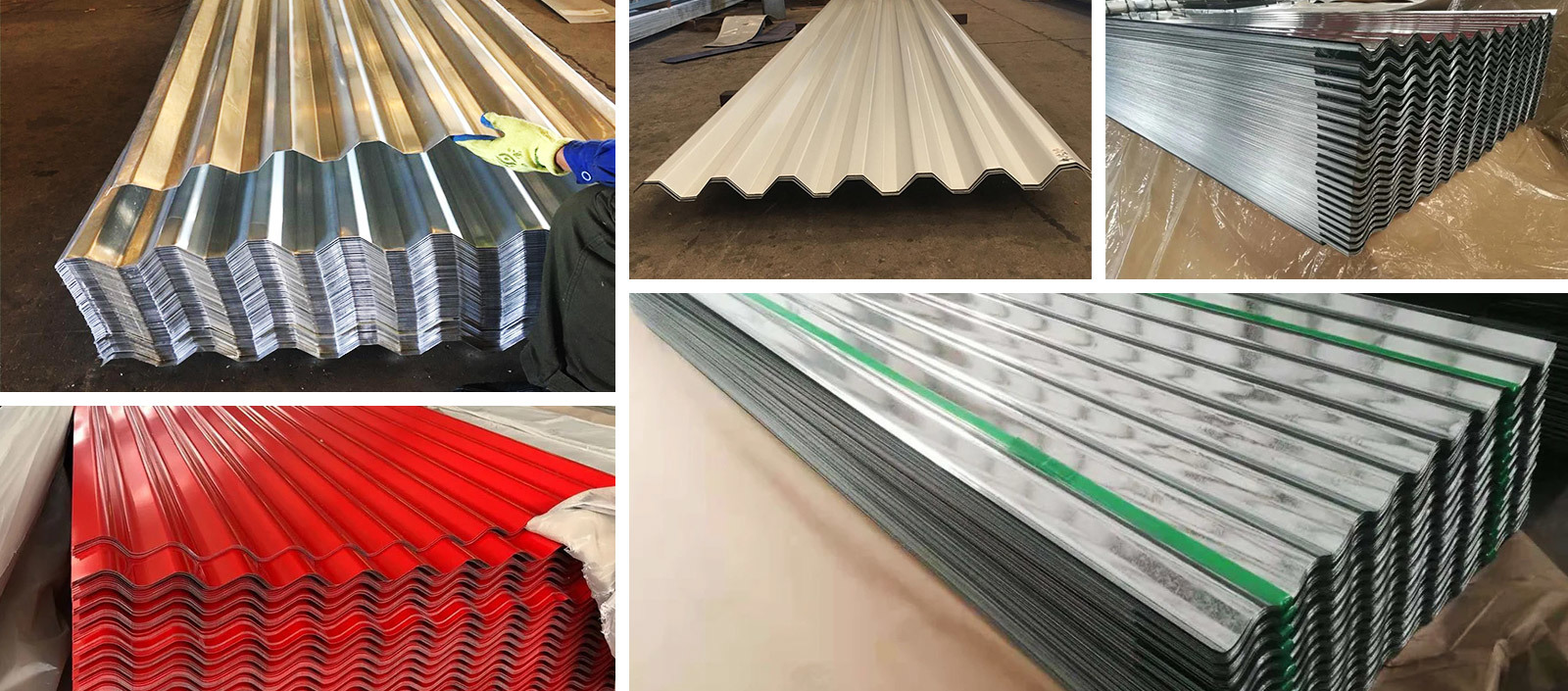

CGCC color coated corrugated roof sheet

Classification :

coating at the same thickness is better than that of hot-dip galvanized products.

According to the test, under the same conditions, according to the

American standard (ASTMB 114), the red rust resistance time of a micron

coating is 12 hours for electrogalvanizing and less than 10 hours for hot

galvanizing. However, it is very difficult to obtain a thick electro-galvanized

coating (large power consumption, high cost, and technical difficulty).

As a color-coated substrate, the use of electro-galvanized is also

mainly applied to home appliances, steel furniture, doors and windows, and the like.

Keywords:

Corrugated Roofing Sheet

Product information

The galvanized varieties used for color-coated steel plates for construction are galvanized and alloy coated products. Their performance differences and uses are as follows:

Hot galvanized

The hot-dip galvanizing referred to here refers to hot-dip galvanized pure zinc. It is most widely used in construction. Before it was used as a color-coated substrate, it has been widely used in the construction industry and is currently the main variety of color-coated substrates for construction. Excellent corrosion resistance. Suitable for making building exterior panels. It can process a variety of levels such as general molding, stamping and deep drawing.

Hot-dip galvanized The coating composition of this product is approximately 55% aluminum, 1.5% silicon, and the rest is zinc. It is characterized by excellent atmospheric corrosion resistance, 2-6 times that of galvanized sheet, and excellent corrosion resistance. It also has high temperature corrosion resistance of aluminum plate, smooth surface and good appearance, but the forming and welding properties of the plating layer are slightly worse. It is suitable for building exterior panels, and can be processed in various levels such as general molding and mechanical bite. Hot-dip galvanized aluminum

The composition of the coating is 5% aluminum, 0.1% mixed rare earth elements, and the rest is zinc. It is characterized by good coating formability and atmospheric corrosion resistance 2-3 times that of hot-dip galvanized sheet. Good applicability and welding performance. Compared with hot-dip galvanized steel sheet, zinc flower is small and rarely used in bare state.

| Product Name | Color Coated Roof Sheet |

| Length | 1000-12000mm |

| Width | 762-1250mm/600-1100mm(before/after corrugated) |

| Tolerance | +/-0.02mm |

| Zinc Coating | 30-275g/m2 |

| Top Paint | 15-25um |

| Bottom paint | 5-7 um |

| Surface | unoil, dry, chromate passiveated, non-chromate passivated |

| Sample | A4 size free of charge |

Product details

Color Coated Steel Feature Excellent Decorativeness, Bendability,Corrosion Resistance,Coating Adhesion And Color Fastness.They Are Ideal Substitutes For Wood Panels In The Construction Industry Because Of Their Good Economic Features Such As Convenient Installation,Conservation Of Energy And Resistance To Contamination.Color Steel Sheets With Surface Texturing On The Surface Has Extremely Superb Anti-Scratch Qualities.Can Be Produced In Various Colors,And Has Credible Quality And Can Be Mass-Produced Economically.

Application:

1.Buildings And Constructions Workshop,Warehouse,Corrugated Roof And Wall,Rainwater,Drainage Pipe,Roller Shutter Door

2.Electrical ApplianceRefrigerator,Washer,Switch Cabinet,Instrument Cabinate,Air Conditioning,Micro-Wave Oven,Bread Maker

3.Furniture Central Heating Slice,Lampshade,Book Shelf

4.Carrying Trade Exterior Decoration Of Auto And Train,Clapboard,Container,Lsolation Board

5.Others: Writing Panel,Garbage Can,Billboard,Timekeeper,Typewriter,Instrument Panel,Weight Sensor,Photographic Equipment.

warehouse storage

The annual output of the factory is 400,000 tons, and the current inventory is more than 100,000 tons, which can greatly save the purchasing time of customers and ensure the production cycle and product quality of customers. We are a quality partner for domestic and foreign customers. At present, there are 14 steel production lines for processing, bending, coating, heat treatment, cutting, drilling, chamfering, conditioning, surface treatment and 13 sets of processing equipment.

Packing and shipping

Our main products are: carbon steel plate, carbon steel pipe, carbon steel coil, stainless steel plate, stainless steel coil, stainless steel profile, galvanized plate, galvanized coil, color coated steel coil, ppgi/ppgl and a wide range of high quality steel products.

Customer visit

Li Cheng (Shandong) Metal Materials Co., LTD. has the right to import and export, and its products are exported to more than 20 countries in Asia, Africa, Europe, North America and other regions. Complete processing equipment, perfect quality assurance system, well received by customers.We are willing to first-class technology, first-class equipment, first-class service wholeheartedly and friends from all walks of life sincere cooperation!

Cooperation Case

Applicable to construction, petroleum, chemical, electric power, metallurgy, urban gas, heat pipe network, Bridges, railways, vehicles, ships and other industrial fields and construction, infrastructure and other engineering fields. Complete testing equipment, strong technical force, can implement GB, ASTM, JIS, DIN and other standards.

HONOR

Factory

FACTORY

FACTORY

FACTORY

FACTORY

FACTORY

FACTORY

RELATED PRODUCTS

GET A FREE QUOTE