PRODUCT CENTER

The purity of the coating is high, so the corrosion resistance of the

coating at the same thickness is better than that of hot-dip galvanized products.

According to the test, under the same conditions, according to the

American standard (ASTMB 114), the red rust resistance time of a micron

coating is 12 hours for electrogalvanizing and less than 10 hours for hot

galvanizing. However, it is very difficult to obtain a thick electro-galvanized

coating (large power consumption, high cost, and technical difficulty).

As a color-coated substrate, the use of electro-galvanized is also

mainly applied to home appliances, steel furniture, doors and windows, and the like.

coating at the same thickness is better than that of hot-dip galvanized products.

According to the test, under the same conditions, according to the

American standard (ASTMB 114), the red rust resistance time of a micron

coating is 12 hours for electrogalvanizing and less than 10 hours for hot

galvanizing. However, it is very difficult to obtain a thick electro-galvanized

coating (large power consumption, high cost, and technical difficulty).

As a color-coated substrate, the use of electro-galvanized is also

mainly applied to home appliances, steel furniture, doors and windows, and the like.

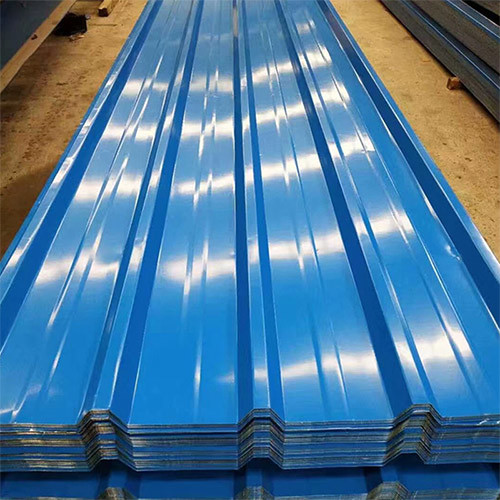

We can also provide galvanized plain

and corrugated sheets with required length.

Galvanized corrugated sheet can be produced

with closed tolerance of standard depth, pitch and width.

and corrugated sheets with required length.

Galvanized corrugated sheet can be produced

with closed tolerance of standard depth, pitch and width.

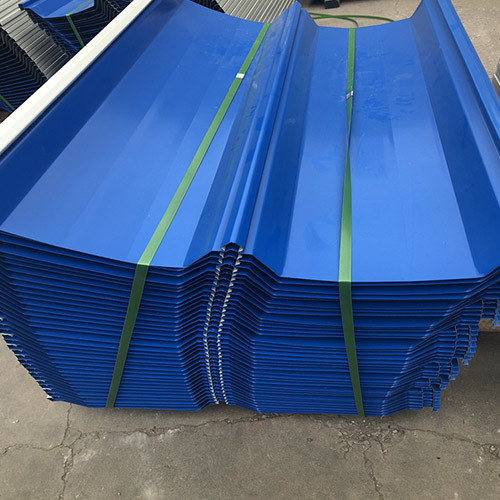

PPGI corrugated steel roof sheets

widely used in construction,

factory,simple house.Its easy installation,

beautiful view,light weight is more popular with people.

widely used in construction,

factory,simple house.Its easy installation,

beautiful view,light weight is more popular with people.

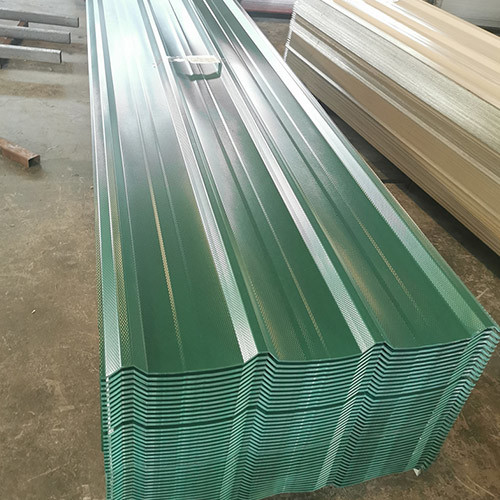

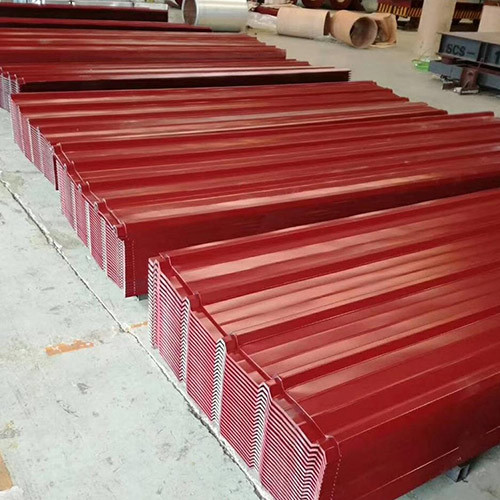

Pressed corrugated steel sheet (roofing sheet) refers to the steel sheet formed by cold pressing or cold rolling.

The steel sheet is made of coloured steel sheet, galvanized steel sheet, stainless steel sheet, aluminium sheet,

anticorrosive steel sheet or other thin steel sheet. The profiled steel sheet has the characteristics of light weight,

high strength, low price, good seismic performance, fast construction and beautiful appearance.The corrugated

metal is a good building material, mainly used for guardrail, floor and other buildings, such as airport terminal,

railway station, stadium, concert hall, grand theatre, etc. According to different application requirements, the

profiled steel sheet can be pressed into a wave type, a T type, a V type, a rib type and the like.

The steel sheet is made of coloured steel sheet, galvanized steel sheet, stainless steel sheet, aluminium sheet,

anticorrosive steel sheet or other thin steel sheet. The profiled steel sheet has the characteristics of light weight,

high strength, low price, good seismic performance, fast construction and beautiful appearance.The corrugated

metal is a good building material, mainly used for guardrail, floor and other buildings, such as airport terminal,

railway station, stadium, concert hall, grand theatre, etc. According to different application requirements, the

profiled steel sheet can be pressed into a wave type, a T type, a V type, a rib type and the like.

Corrugated steel sheet is also called profiled sheet,

which is made of color coated steel sheet, galvanized

sheet and other metal sheets by rolling and cold

bending into profiled sheets of various wave shapes.

which is made of color coated steel sheet, galvanized

sheet and other metal sheets by rolling and cold

bending into profiled sheets of various wave shapes.